Reduced pump’s operating temperature

Reduced Mean Time Between Failure (MTBF) by eliminating premature failure

Created a custom solution that OEM couldn’t provide

Quality parts and service to repair all OEM pumps and motors

SPM™ Oil & Gas’ (SPM) five Centres of Manufacturing and Engineering Excellence across the Middle East enables companies using pumps, motors, rotating equipment and more to reduce total cost of ownership (TCO) and extend equipment life through superior-quality parts and engineering expertise.

A power station in the Persian Gulf experienced significant issues with one of its European-manufactured pumps, leading to repeated premature failure of the equipment. The pump’s bearing housing contributed to excessive heat buildup, which caused the pump to overheat. The pump’s OEM was unable to develop a suitable solution, so the facility approached SPM to provide a quick and efficient resolution.

SPM™’s APS team at its Centre of Manufacturing and Engineering Excellence in Dubai applied its technical expertise to diagnose the problem. SPM™ scanned the pump using its state-of-the-art laser scanning system. This allowed SPM™ engineers to create a full CAD drawing of the equipment, which was used to recommend modifications to the pump design. In addition to adding cooling fins to eliminate overheating, SPM™’s engineers determined the pump’s existing bearing housing required reinforcement to strengthen the original design.

The Dubai workshop’s technicians manufactured the modified bearing housing, enabling the pump to dissipate more heat than the original standard design. With the new features, the power station reported a significant drop in the pump’s operating temperature and a reduction in NPT, which enabled the pump to run throughout the summer without tripping.

SPM™’s five state-of-the-art Centres of Manufacturing and Engineering Excellence across the Middle East and in-country engineering expertise assure best-in-class quality, delivery and responsiveness for plants across the Eastern Hemisphere. SPM™ can solve engineering challenges and improve efficiencies with a global product offering and localized service capabilities that meet the needs of each operating environment.

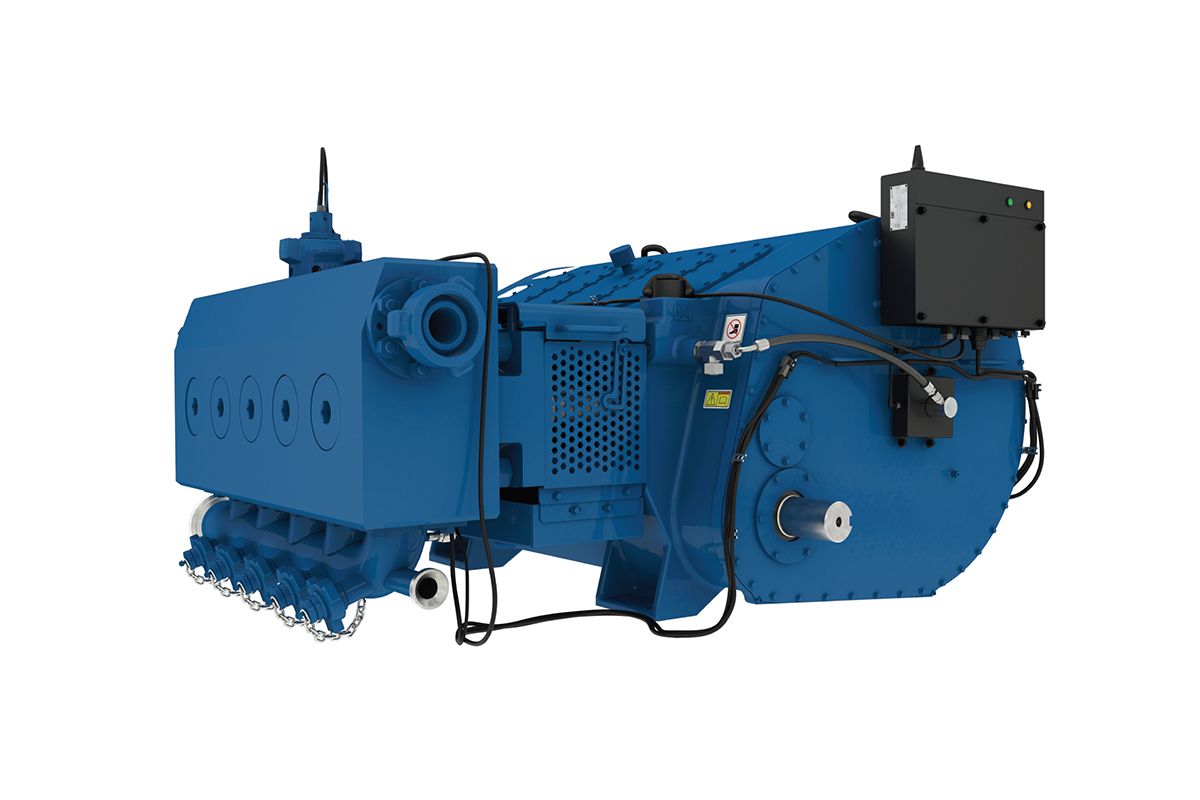

Downtime and non-productive time (NPT) are the enemies of pressure pumping companies across every basin. Conventional frac pumps can crack as companies push equipment to near-continuous duty, increasing capital and operating expenses. SPM™ Oil & Gas engineers designed the SPM™ WS 335 Frac Pump to eliminate a leading cause of pump failure and resulting NPT to meet companies’ uptime demands.

Learn MoreEfficiency is always top of mind in the oil and gas industry, but how do companies achieve maximum efficiencies? By using innovative solutions to transform the performance and longevity of their pump consumable parts. The SPM™ EdgeX Carbide Seat’s innovative design supports pressure pumpers’ continuous pursuit of reduced downtime and costs to meet the demands of the field and workforce.

Learn MoreThe SPM™ Oil & Gas Fort Worth Service Center holds the distinction of being the Pump Center of Excellence in the SPM Edge Service Center network, which ensures the Fort Worth service team is at the forefront of pressure pumping advancements and knowledge.

Learn MoreThe high-performance SPM EdgeX Valve and EdgeX Carbide Seat are built to withstand the wear-and-tear of today’s pumping conditions.

Learn More