Welcome to SPM™ Oil & Gas

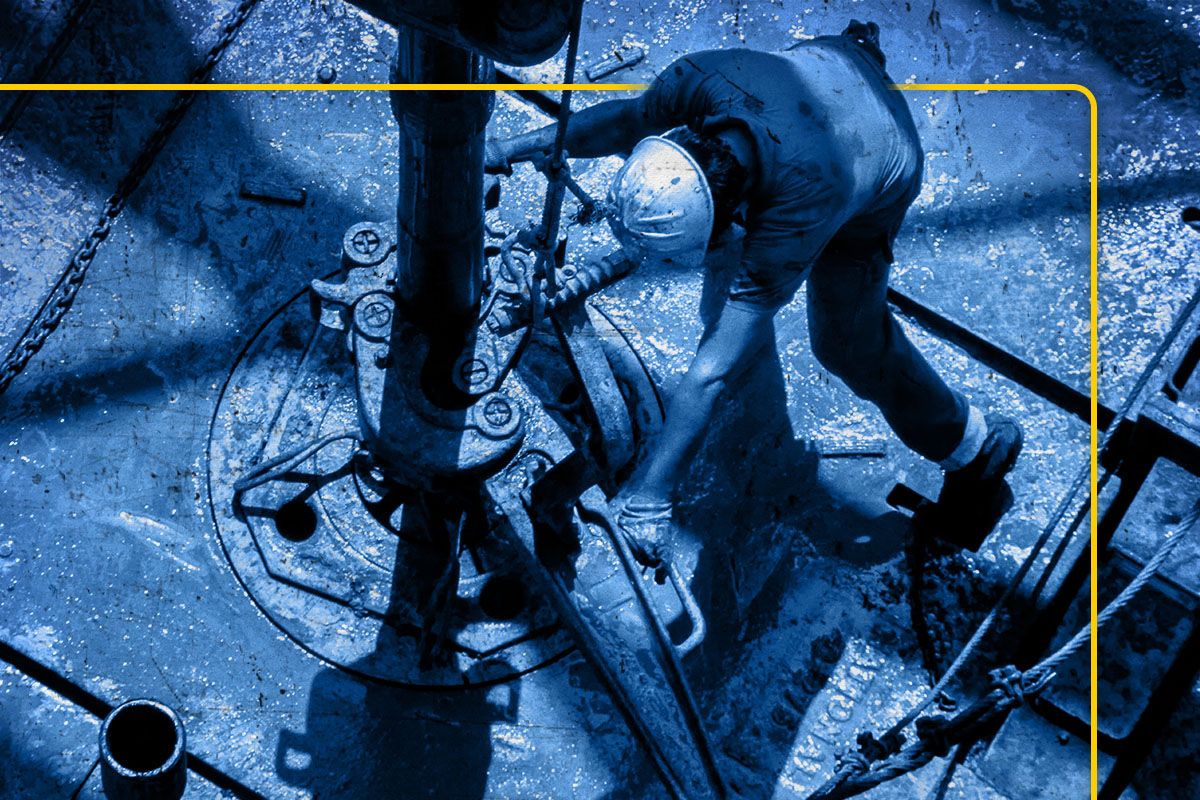

SPM™ Oil & Gas is a global provider of surface frac solutions, bringing you quality products that keep the oilfield moving. Backed by the power of Caterpillar, SPM Oil & Gas is set to improve the lives of those in the communities where we work.

Through a distinguished network of trusted and proven oilfield products, combined with the best minds in the industry, SPM solves and prevents the most common frac site problems for operators, engineers and every vested stakeholder. With a global network of service locations and engineer field teams in every major basin, you're never alone on the oilfield when you choose SPM.

SPM™ Oil & Gas Industry Solutions

The right products. The right people. The right solutions.

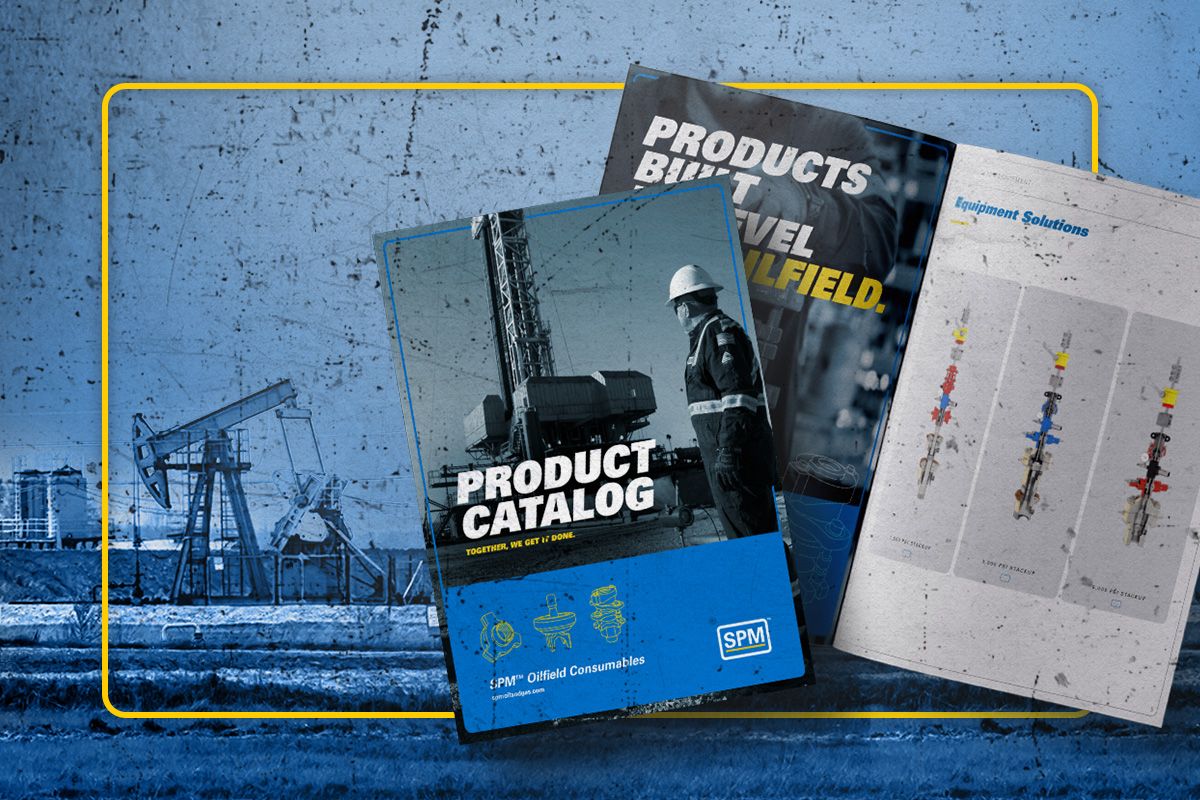

Resources & Knowledge Hub

Stay up to date on all things oil and gas.